由罗杰斯公司发布

先进电子解决方案

电力电子也在迅速发展。新的封装技术正面临着芯片温度上升的挑战,这在电动汽车/混合动力汽车 (EV/HEV) 等应用中也有所体现。电子器件需要具备更长的使用寿命,才能在恶劣工况下工作,例如风力涡轮机。Power electronics based on SiC components need to handle faster switching in the face of higher temperatures. While beneficial, the challenge is that these changes produce considerable stress on power systems and, consequently, result in reliability problems.

Traditional power module designs were primarily based on Al2O3 or AlN ceramics. But the need for higher performance is leading designers to choose more advanced substrates. substrates with Si3N4 ceramics use the excellent bending strength, high fracture toughness, and good thermal conductivity of Si3N4 to build substrates that can handle a variety of today’s challenges.

In the following video, the Power Electronics Solutions team at Rogers takes a look at how to make the right substrate choices to support demanding applications.

VIDEO: 3 Steps to Select the Right DBC / AMB Ceramic Substrate for Your Application

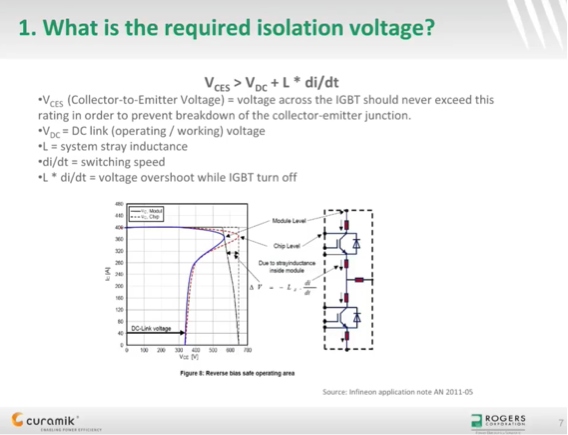

In this video, Olivier Mathieu, Product Innovation Manager, discusses how to use the latest substrates in power electronics designs. He walks us through: (a) How to select the right ceramic thickness and its influence on basic isolation voltage, (b) How to select the right ceramic grade and its influence on heat removal, and (c) How to select the right copper thickness and its influence on functional isolation, ampacity, and heat removal.

Watch the video, Selecting the Right DBC / AMB Ceramic Substrate.

标签:

燃油汽车与电动/混合动力汽车、 通用工业

发布于 2017 年 9 月 25 日