由罗杰斯公司发布

先进电子解决方案

随着电子设备尺寸不断缩小,功率不断增加,人们对更高功率密度的电力电子电路的需求也在增长。工作温度升高是提高电路功率密度的结果之一,这会增加现代电力电子电路基板的电路材料热应力。现在,人们可采用新的工艺和材料来应对这些挑战。

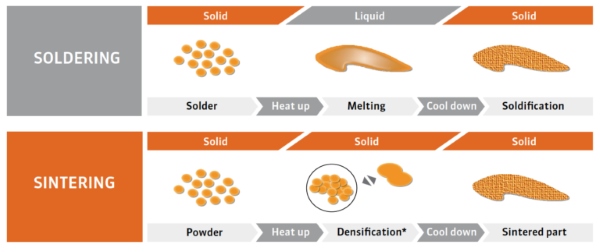

Soldering vs Silver Sintering

Soldering can present a number of complications that reduce a circuit’s performance, such as solder bridges and heel cracking. At higher operating temperatures, solder fatigue becomes an issue. Common die attach technologies are based on soft solders with melting points below 250°C. With the development of new generations of semiconductors (e.g. based on wide band gap materials like SiC and GaN), operating temperatures increase to more than 200°C. This will lead to a significant decrease in the solders‘ strength and reliability.

Sintering is a heat treatment process applied to a powdered material in order to give it higher strength and integrity. Silver sintering has become a promising technology for high temperature power electronics packaging as an alternative to soldering.

In the soldering process, heat is applied until a solid reaches its melting point and is then allowed to cool down and solidify to form a bond. In the silver sintering process, heat is applied to a silver paste, resulting in densification. Several actions occur simultaneously, including grain growth, pore growth, and densification, resulting in a stronger bond.

Find out what you need to know about silver sintering in the tech note: curamik® Substrates for Silver Sintering.

PCB Materials for High Power, High Temp Applications

The requirements for PCB materials capable of supporting high-density power electronics circuits are quite challenging, since they include both mechanical and electrical stability at high temperatures.

To meet these demands, curamik® ADVANTAGE provides a ceramic-materials based solution for smaller, higher power-density PCB circuits in power electronic applications. These ceramic substrates provide low dielectric loss and low-loss copper conductors that support high voltages and currents in power-grid, energy, and industrial power applications.

To improve the performance and usability of the substrate materials, all curamik ADVANTAGE products include a choice of plating materials, addition of solder stop to control solder coverage, and treatment for surface roughness. As an alternative to soldering, a state-of-the-art silver sintering process provides an attachment option to solder for critical high-temperature applications

Download the Power Magazine article for more details: Tailoring Circuit Materials for Power Electronic Applications

Watch the curamik ADVANTAGE video:

发布于 2017 年 7 月 25 日