由罗杰斯公司发布

Elastomeric Material Solutions, Enclosure Institute

Welcome back to the Enclosure Institute™, your go-to resource for mastering enclosure design and sealing solutions.

In this fifth blog of The Enclosure Institute™ series, we will examine eight gasket materials and when to use them.

Sealing an enclosure is not just about filling a gap, it’s about selecting the right material to ensure long-term performance.

Seals and gaskets play a crucial role in protecting enclosures from moisture, dust, chemicals, and temperature extremes. However, not all materials perform equally under different conditions. Factors like compressibility, environmental exposure, sealing effectiveness, and material specifications must be carefully evaluated to ensure durability and performance.

From high-performance silicones that withstand extreme temperatures to cost-effective neoprenes for basic, one-time sealing needs, we’ll review the most commonly-used materials, their strengths, trade-offs, and ideal applications.

Image property of Rogers Corporation

Top 8 Enclosure Gasket Materials Overview

| Material | Best For | Advantages | Disadvantages | 成本 |

|---|---|---|---|---|

| Silicone Foam (BISCO) | Extreme temperature ranges, fire resistance, UV protection | Wide temperature range, excellent flame resistance, UV/ozone resistance, low outgassing | Abrasion resistance, higher cost, may require additional processing for strong bonding | High |

| Silicone Sponge (HCR-Based) | High-temperature applications requiring tear strength and UV resistance | Wide temperature range, UV/ozone resistance, good tear strength | Higher cost, may be too firm for some sealing applications | Moderately High |

| Polyurethane (PORON) | Sealing applications requiring compression set resistance and long-term flexibility | Excellent compression set resistance, low outgassing, low stress relaxation | Absorbs water when uncompressed, limited acid/base resistance | Medium |

| Neoprene | Abrasion resistance and acid/base protection | Great abrasion resistance, good acid/base resistance | Poor compression set resistance and force relaxation | Low |

| EPDM | Outdoor applications requiring UV, ozone, and low-temperature resistance | Excellent UV/ozone resistance, good abrasion resistance, low-temperature flexibility | Poor petroleum and acid resistance, potential outgassing | Medium |

| Vinyl Nitrile | Oil and chemical resistance applications | Strong resistance to petroleum and chemicals | Poor compression set resistance, force relaxation, outgassing | Medium |

| PVC | Lightweight, low-cost applications needing UV resistance | UV-resistant, solvent/chemical resistance | Narrow temperature range, outgassing, limited PSA anchorage | Low |

| Polyethylene | Low-cost, abrasion-resistant applications | Low water absorption, strong tear strength, abrasion resistance | Poor compression set resistance, force relaxation, limited PSA anchorage | Low |

1. Silicone Foam (ex: BISCO® silicone foam)

Best for: Extreme temperature ranges, fire resistance, and UV protection

- Advantages: Withstands a wide temperature range, excellent flame resistance, UV/ozone resistance, excellent chemical resistance, and low outgassing.

- Disadvantages: Abrasion resistance, higher cost, may require additional processing for strong bonding to certain substrates

2. Silicone Sponge (HCR-Based)

Best for: High-temperature applications requiring tear strength and UV resistance

- Advantages: Offers a wide temperature range, UV/ozone resistance, excellent chemical resistance, and good tear strength.

- Disadvantages: Higher cost, sometimes too firm for sealing, may require additional processing for strong bonding to certain substrates

3. Polyurethane (example: PORON® polyurethane – Medium/High Density)

Best for: Sealing applications requiring compression set resistance (C-Set) and long-term flexibility

- Advantages: Excellent C-Set resistance, excellent sealing when compressed, low outgassing, low stress relaxation.

- Disadvantages: UV resistance, temperature range limitations

4. Neoprene

Best for: Abrasion resistance and acid/base protection

- Advantages: Excellent elongation, great abrasion resistance, good acid/base resistance.

- Disadvantages: Poor C-Set resistance and stress relaxation.

5. EPDM

Best for: Outdoor applications requiring UV, ozone, and low-temperature resistance

- Advantages: Excellent UV/ozone resistance, good abrasion resistance, low-temperature flexibility.

- Disadvantages: Poor petroleum and acid resistance, potential outgassing.

6. Vinyl Nitrile

Best for: Oil and chemical resistance applications

- Advantages: Strong resistance to petroleum and chemicals. Flexibility and conformability.

- Disadvantages: Poor C-Set resistance, stress relaxation, and outgassing. Fair UV resistance.

7. PVC

Best for: Lightweight, low-cost applications needing UV resistance

- Advantages: UV-resistant, solvent/chemical resistance.

- Disadvantages: Narrow temperature range, outgassing, limited PSA anchorage. Disposal can have a negative environmental impact.

8. Polyethylene

Best for: Low-cost, abrasion-resistant applications

- Advantages: Low water absorption, strong tear strength, abrasion resistance.

- Disadvantages: Poor C-Set resistance, stress relaxation, limited PSA anchorage.

Enclosure Gasket Material Key Properties Overview

| Material | Temperature Range | Compression Set Resistance | 耐化学腐蚀 | 密封 | 抗紫外线/耐臭氧性 | Application Suitability |

|---|---|---|---|---|---|---|

| Silicone Foam (BISCO) | Wide (-55°C to 200°C) | Excellent (<5%) | 良 | Excellent with compression | 优 | Extreme environments, high heat, outdoor exposure |

| Silicone Sponge (HCR-Based) Wide (-55ÂC to 200°C) | 良 | (<5-20%) | 良 | 良 | 优 | High-temperature sealing, UV exposure |

| Polyurethane (PORON)Moderate (-40°C to 90°C) | 优 | (<5-10%) | Moderate | Excellent with compression | Moderate | Compression sealing, flexible applications |

| Neoprene | Moderate (-40°C to 100°C) | 差 | 良 | 良 | 差 | Abrasion resistance, industrial gaskets |

| EPDM | Wide (-50°C to 150°C) | Moderate | Moderate | 优 | 优 | Outdoor sealing, weather-resistant gaskets |

| Vinyl Nitrile | Moderate (-30°C to 100°C) | 差 | 优 | 良 | Moderate | Oil and fuel exposure, industrial use |

| PVC | Narrow (-10°C to 60°C) | 差 | 良 | Moderate | 良 | Low-cost UV-resistant sealing |

| Polyethylene | Moderate (-40°C to 100°C) | 差 | Moderate | 优 | Moderate | Budget-friendly abrasion-resistant sealing |

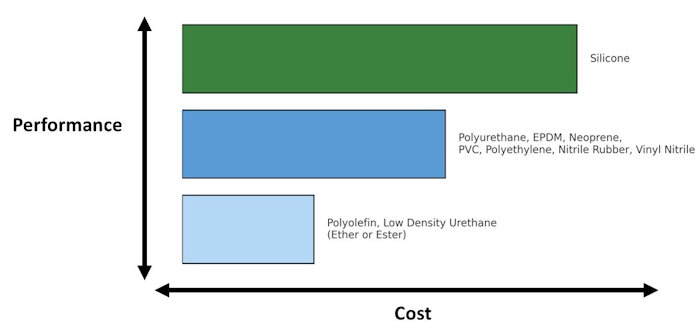

Cost-Performance Balance: Finding the Right Fit

Striking a balance between upfront costs and long-term performance is essential in material selection.

Here’s a quick comparison between silicone, polyurethanes, and other everyday foams:

- Silicone materials have a higher upfront cost but excel in durability and long-term sealing performance, reducing replacement needs.

- Polyurethane materials are more cost-effective for applications with moderate performance requirements.

- Neoprene, vinyl nitrile, and polyethylene offer more budget-friendly options with trade-offs in longevity and resistance.

Value Beyond Cost

Consider the total cost of ownership, including maintenance, downtime, and potential failures.

Material Recommendations by Application

Here is some general guidance for some material options based on the application. As always, material choice is dependent on application requirements.

| 应用 | Recommended Material | Key Benefits |

|---|---|---|

| Outdoor Sealing | BISCO silicone | UV/Ozone resistance, high durability |

| Dynamic Applications | BISCO silicone and/or PORON polyurethane | High compression set resistance, durability |

| Harsh Chemical/Oils | Specialized silicones like ARLON® Industrial Fluorosilicones | Resistance to aggressive chemicals |

| General Sealing, Moderate Environments | PORON polyurethane | Cost-effective, moderate performance |

| 耐磨性好 | Silicone sponge, neoprene, polyethylene | Strong tear strength, good wear resistance |

Key Points in Choosing the Right Gasket Material

- Gasket material selection should balance performance, durability, and cost.

- Key factors to consider include:

- Environmental exposure (UV, temperature, moisture)

- 耐化学性

- Compression and recovery needs

- Application-specific mechanical stress

- Not all materials perform equally, what works in one environment may fail in another.

- Prioritize long-term performance over short-term cost savings to avoid premature failure, maintenance issues, or compliance risks.

- A well-chosen material supports long-term reliability, better equipment protection, and reduced total cost of ownership.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you The Enclosure Institute™—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for The Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

发布于 2025 年 5 月 28 日

Institute Insight

Institute Insight